Zhejiang Hangzhou sound measuring tube, Wenzhou sound measuring tube, Ningbo sound measuring tube, Shaoxing sound measuring tube, Jiaxing sound measuring tube, Jinhua sound measuring tube, Zhoushan sound measuring tube, Huzhou sound measuring tube, Taizhou sound measuring tube, Zhangzhou sound measuring tube Lishui sound tube Jiangxi sound tube Nanchang sound tube, Jiujiang sound tube, Jingdezhen sound tube, Pingxiang sound tube, Xinyu sound tube, Yingtan sound tube, Zhangzhou sound tube, Yichun sound tube, Shangrao Sound tube, Ji'an sound tube, Fuzhou sound tube

Construction process

The detection tube is based on the principle of reliability and convenience. When the steel bar is made, the steel bar is first spliced and mounted, and then the steel bar is connected and positioned. The steel cage is installed in the bottom cage and the wire is bundled at the upper part, and the wire is bundled every 2-3 meters. One. Ensure that the test tube is positioned vertically, which is good for pile foundation detection and prevents concrete pipe collision.

First, the length of the test tube fixed length test tube is based on the length of the steel cage, the bottom tube should be slightly longer than the bottom of the steel cage 20-30 cm

Second, the detection tube bottom cage installation

The bottom tube of the test tube is equipped with a movable clamp, which is positioned according to the actual construction conditions, and then welded to the steel cage to fix the detection tube to prevent floating and rotating.

Third, the detection tube cage installation

After the steel cage is formed, the connecting tube is installed in the detecting tube. The U-shaped steel bar is positioned on the upper part of the detecting tube, and the upper and lower sides can be slid. The one end of the socket is positioned with the S-shaped steel bar hook. When the steel cage is installed, the S-shaped hook is removed and the detecting tube is removed. Slide down, insert the bottom tube, and then tighten the nut with a wrench. Bundle and fix it with iron wire every 2-3 meters in the middle. And so on

Fourth, the detection tube top cage installation

After the steel bar cage is installed, all the joints of the test tube are completed, ensure that the tightening is firm, the test tube must be filled with clean water, and finally the special head is screwed. All the operation processes are completed.

5. When the test tube is installed in a half cage

The detection tube can be segmented and welded according to the actual situation, which is convenient for positioning the steel hoop. It can also be installed without the steel cage. Compared with other joints, it can save 3 steel bars and is safe and convenient.

The latest technical data of the sound tube industry in Henan steel industry is provided by Jin Jun Guanye Yang Yang.

Http://news.chinawj.com.cn

Http://news.chinawj.com.cn  Submission:

Submission:  ---

**Improved and Rewritten Version in English (Over 500 Characters):**

The sound measuring tubes used in construction projects such as those in Zhengzhou, Luoyang, Kaifeng, and Luohe play a crucial role in pile foundation testing. These tubes are essential tools for non-destructive testing, allowing engineers to assess the integrity of deep foundations.

In the construction process, the detection tubes are designed with reliability and ease of use in mind. They are typically manufactured using high-quality steel and are installed alongside the reinforcing steel cage. The installation begins with splicing and mounting the steel bars, followed by precise positioning of the steel cage. At the top of the structure, wires are bundled every 2–3 meters to ensure stability and vertical alignment. This helps prevent any misalignment or damage during the pouring of concrete.

The length of the detection tube is determined based on the size of the steel cage. The bottom section of the tube is usually extended by about 20–30 cm beyond the base of the cage to ensure full coverage. A movable clamp is attached to the bottom of the tube, which is then welded to the steel cage to prevent movement or rotation during the construction process.

For the installation of the detection tube cage, a U-shaped steel bar is placed on the top of the tube, allowing for smooth sliding. One end of the connector is secured with an S-shaped steel bar hook. Once the steel cage is in place, the hook is removed, and the tube is lowered into position. The bottom tube is inserted, and the connection is tightened with a wrench. The tube is then tied and fixed with wire at regular intervals to maintain its stability throughout the project.

At the top of the structure, once the entire steel cage is installed, all the joints of the detection tube are inspected and tightened. The tube is then filled with clean water to ensure there are no leaks, and a special cap is securely fastened to complete the process.

When installing the detection tube in a partial cage setup, the tube can be segmented and welded according to site-specific conditions. This method not only simplifies the installation but also reduces the need for three additional steel bars compared to traditional methods. It offers a safer and more efficient alternative for various types of construction projects.

This technique has been widely adopted across different regions, including cities like Hangzhou, Wenzhou, Ningbo, and Shaoxing in Zhejiang Province, as well as Nanchang, Jiujiang, and other locations in Jiangxi Province. The use of sound measuring tubes ensures accurate data collection and enhances the overall quality of foundation testing.

For more information on the latest developments in sound tube technology, you can visit [http://news.chinawj.com.cn](http://news.chinawj.com.cn) or contact us at 15731791996.

---

**Improved and Rewritten Version in English (Over 500 Characters):**

The sound measuring tubes used in construction projects such as those in Zhengzhou, Luoyang, Kaifeng, and Luohe play a crucial role in pile foundation testing. These tubes are essential tools for non-destructive testing, allowing engineers to assess the integrity of deep foundations.

In the construction process, the detection tubes are designed with reliability and ease of use in mind. They are typically manufactured using high-quality steel and are installed alongside the reinforcing steel cage. The installation begins with splicing and mounting the steel bars, followed by precise positioning of the steel cage. At the top of the structure, wires are bundled every 2–3 meters to ensure stability and vertical alignment. This helps prevent any misalignment or damage during the pouring of concrete.

The length of the detection tube is determined based on the size of the steel cage. The bottom section of the tube is usually extended by about 20–30 cm beyond the base of the cage to ensure full coverage. A movable clamp is attached to the bottom of the tube, which is then welded to the steel cage to prevent movement or rotation during the construction process.

For the installation of the detection tube cage, a U-shaped steel bar is placed on the top of the tube, allowing for smooth sliding. One end of the connector is secured with an S-shaped steel bar hook. Once the steel cage is in place, the hook is removed, and the tube is lowered into position. The bottom tube is inserted, and the connection is tightened with a wrench. The tube is then tied and fixed with wire at regular intervals to maintain its stability throughout the project.

At the top of the structure, once the entire steel cage is installed, all the joints of the detection tube are inspected and tightened. The tube is then filled with clean water to ensure there are no leaks, and a special cap is securely fastened to complete the process.

When installing the detection tube in a partial cage setup, the tube can be segmented and welded according to site-specific conditions. This method not only simplifies the installation but also reduces the need for three additional steel bars compared to traditional methods. It offers a safer and more efficient alternative for various types of construction projects.

This technique has been widely adopted across different regions, including cities like Hangzhou, Wenzhou, Ningbo, and Shaoxing in Zhejiang Province, as well as Nanchang, Jiujiang, and other locations in Jiangxi Province. The use of sound measuring tubes ensures accurate data collection and enhances the overall quality of foundation testing.

For more information on the latest developments in sound tube technology, you can visit [http://news.chinawj.com.cn](http://news.chinawj.com.cn) or contact us at 15731791996.Optical Flats mirrors are ideal for a variety of applications including interferometry, imaging systems, laser applications, optical path folding, and autocollimation. These mirrors are available in a variety of coating and substrate options, along with surface flatness options of λ/10 and λ/20. Fused Silica, is optically clear and features excellent resistance to abrasion and high durability, making it the best choice for applications in harsh environments.

The mirrors are available in circular, square, and rectangular dimensions. Rectangular first surface mirrors are ideal for applications requiring the mirror to be mounted at 45° in order to produce a 90° bend in the light path.

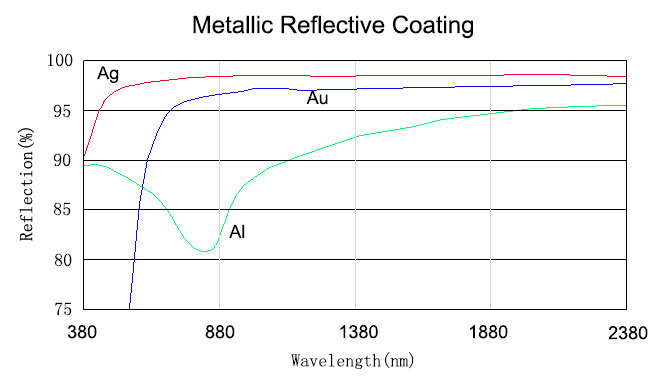

Protected metallic coatings provide a moderate level of reflection over a very broad spectral range and are widely used as mirrors. These coatings are protected by a thin layer of dielectric material in order to make them durable. Enhanced metallic coatings provide greater reflection across the operating band width. These coatings are enhanced by adding a multilayer dielectric stack. Metal coatings will modify the state of polarization of an incident beam of light and are therefore inappropriate for most polarization sensitive applications.

+

Optical Glass Flat Mirror,Optical Glass Protective Flat Mirror,Al Protective Mirror,Aluminium Flat Mirror

China Star Optics Technology Co.,Ltd. , https://www.csoptlens.com