Please Note: Lifting and lifting systems involve the use of multiple tools, variables, and devices, and polyester web slings are just one component of that system. It's crucial that you read and fully understand this bulletin before using polyester web slings. Failure to do so might lead to severe INJURY or even death due to sling failure or load loss.

Proper inspection and maintenance of your synthetic lifting slings are vital to ensure safety and prolong their lifespan. Here's a detailed guide to help you keep your slings in excellent condition.

Inspection Guidelines

1. Visual Inspection:

Before every use, carefully inspect the sling for any visible damage. Look for cuts, tears, or abrasions on the webbing. Check for broken stitches or signs of chemical damage, such as discoloration.

2. Manual Check for Damage:

Run your hands along the sling to feel for any hidden damage. Pay attention to stiffness, which could signal chemical exposure or heat damage. Ensure there are no hard spots or thinning areas.

3. Hardware Examination:

Check all hardware components, including hooks and shackles, for wear, corrosion, or damage. Make sure all attachments are secure and functioning properly.

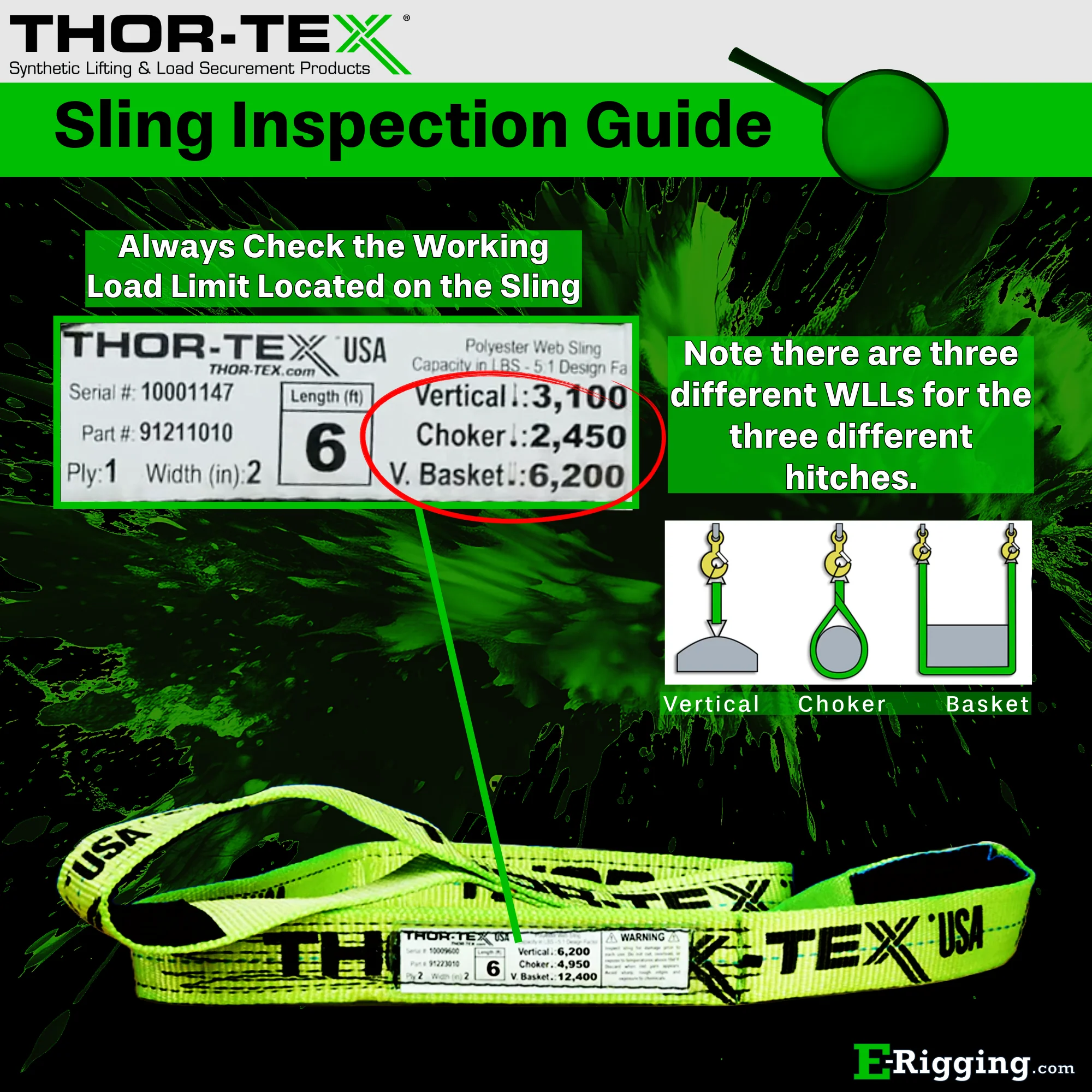

4. Load Capacity Verification:

Ensure the sling remains within its rated load capacity. If the tag indicating the Working Load Limit (WLL) is missing or unreadable, take the sling out of service immediately.

Maintenance Tips

1. Regular Cleaning:

Keep your slings clean by removing dirt, grease, and other contaminants. Use mild soap and water, avoiding harsh chemicals that can weaken the fibers. Rinse thoroughly and let the sling dry completely before storage.

2. Proper Storage:

Store slings in a cool, dry location away from direct sunlight and chemicals. Hanging slings or placing them on racks helps prevent tangling and damage.

3. Avoid Sharp Edges:

When using synthetic slings, avoid dragging them over sharp edges. Use wear pads or edge protectors to minimize the risk of cuts and abrasions.

Protection from Sharp Edges: According to OSHA 1910.184(c)(7), slings must be padded or protected from sharp edges. This means that when using lifting slings with forklifts, there should be padding or protective measures between the forklift forks and the sling to prevent abrasion and tears.

4. Professional Inspections:

Schedule regular inspections by a qualified professional. This should be done at least annually or more frequently if the slings are used in harsh conditions or for critical lifts.

When to Replace a Sling

Dispose of your sling if it exhibits any of the following signs:

- Cuts, tears, or burns in the webbing

- Broken wires or excessive wear in wire rope slings

- Bent, cracked, or damaged chain links

- Melting or weakening of synthetic fibers due to heat exposure

Proper inspection and maintenance of your synthetic lifting slings are essential to ensure safety and efficiency in your lifting operations. By adhering to these guidelines, you can extend the life of your slings and prevent accidents.

For more detailed information on sling safety and best practices, visit our Web Sling Bulletin.

Is it time for you to replace a sling? Consider upgrading to THOR-TEX Slings.

Changzhou Yingda New Material Co., Ltd , https://www.yingdaspc.com