Huiyuan's products are widely used in various industrial applications, including petroleum, chemical, paper, shipbuilding, power generation, and metallurgical sectors. They are commonly found in pipes, valves, flanges, and heat exchangers. Customers have consistently recognized our products as reliable, high-quality solutions that meet the highest industry standards. As a result, the Huiyuan brand has become a trusted name in the sealing industry, known for its professionalism, reliability, and strong brand value. Consumers place their full confidence in Huiyuan due to its long-standing reputation for excellence.

**Detailed Description of the PTFE Gasket Manufacturing Process** 1) **Raw Material Preparation**: The process begins with high-purity F4 (PTFE) materials. Raw F4 fine resin is crushed and sieved to ensure uniform particle size, which is essential for consistent product quality. 2) **Mold Preparation**: Before starting, the mold is cleaned thoroughly using alcohol to remove any impurities or rust. It is crucial that the mold remains clean and free from any foreign substances to ensure the final product meets specifications. 3) **Weighing**: Based on the formula G = PV, where G represents the required feed amount, P is the preform density (2.18g/cm³), and V is the volume of the product, the correct weight of the raw material is measured and prepared. 4) **Feeding**: The F4 resin is evenly distributed across the entire pressing surface to ensure uniform compression during the forming stage. 5) **Pre-forming (Pressing)**: Using calculated gauge pressure, the material is pressed into a preliminary shape. This step helps to compact the resin and prepare it for the sintering process. 6) **Demoulding and Trimming**: Once the pre-form is ready, it is carefully removed from the mold. Any excess material on the edges is trimmed to achieve a smooth surface and neat appearance, preparing the part for the next stage. 7) **Sintering**: The semi-finished gasket is slowly placed into the sintering furnace. The temperature is gradually increased to around 390°C and maintained for one hour. Afterward, the temperature is kept constant for another hour to allow proper melting and bonding of the material. Once the sintering is complete, the gasket is allowed to cool naturally over approximately four hours until it reaches room temperature. At this point, it is considered a finished product and ready for packaging and delivery.

Huiyuan’s commitment to quality and innovation ensures that every PTFE gasket produced meets the most stringent requirements of the industry. Whether you're looking for standard or custom-made gaskets, our products are designed to deliver exceptional performance and durability in even the harshest environments. Http://news.chinawj.com.cn Submission:

**Detailed Description of the PTFE Gasket Manufacturing Process** 1) **Raw Material Preparation**: The process begins with high-purity F4 (PTFE) materials. Raw F4 fine resin is crushed and sieved to ensure uniform particle size, which is essential for consistent product quality. 2) **Mold Preparation**: Before starting, the mold is cleaned thoroughly using alcohol to remove any impurities or rust. It is crucial that the mold remains clean and free from any foreign substances to ensure the final product meets specifications. 3) **Weighing**: Based on the formula G = PV, where G represents the required feed amount, P is the preform density (2.18g/cm³), and V is the volume of the product, the correct weight of the raw material is measured and prepared. 4) **Feeding**: The F4 resin is evenly distributed across the entire pressing surface to ensure uniform compression during the forming stage. 5) **Pre-forming (Pressing)**: Using calculated gauge pressure, the material is pressed into a preliminary shape. This step helps to compact the resin and prepare it for the sintering process. 6) **Demoulding and Trimming**: Once the pre-form is ready, it is carefully removed from the mold. Any excess material on the edges is trimmed to achieve a smooth surface and neat appearance, preparing the part for the next stage. 7) **Sintering**: The semi-finished gasket is slowly placed into the sintering furnace. The temperature is gradually increased to around 390°C and maintained for one hour. Afterward, the temperature is kept constant for another hour to allow proper melting and bonding of the material. Once the sintering is complete, the gasket is allowed to cool naturally over approximately four hours until it reaches room temperature. At this point, it is considered a finished product and ready for packaging and delivery.

Huiyuan’s commitment to quality and innovation ensures that every PTFE gasket produced meets the most stringent requirements of the industry. Whether you're looking for standard or custom-made gaskets, our products are designed to deliver exceptional performance and durability in even the harshest environments. Http://news.chinawj.com.cn Submission:

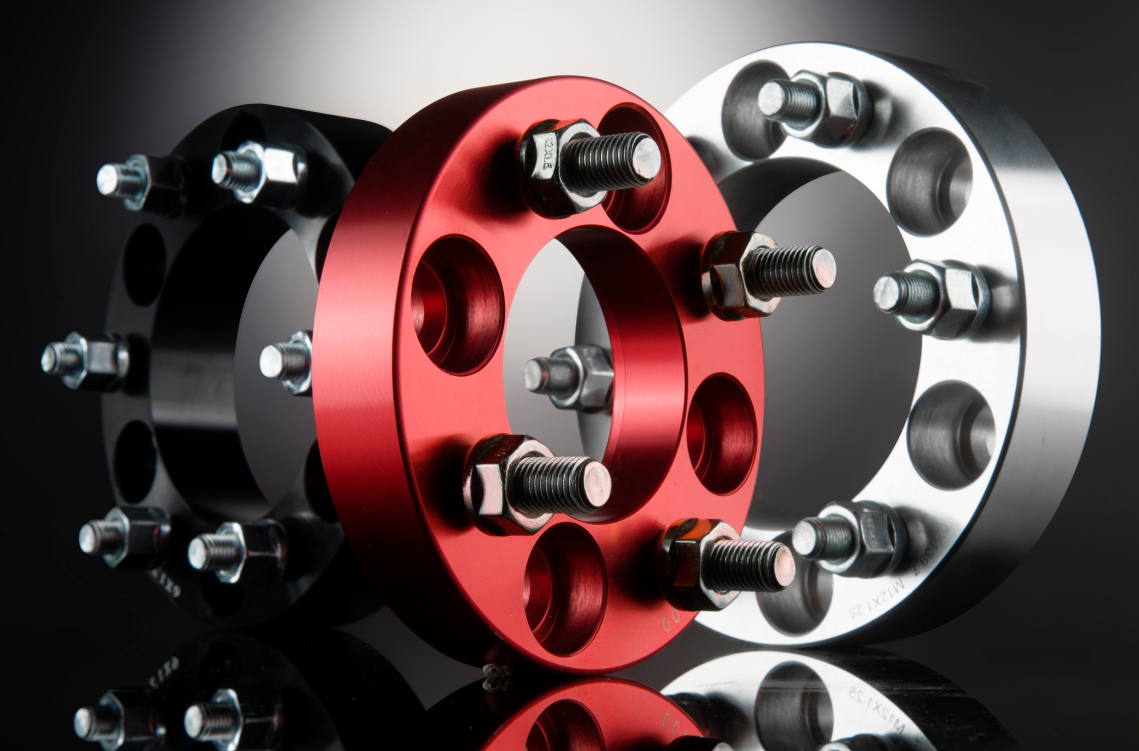

Yokelink providing high-quality wheel accessories, including Wheel boltss, Wheel nuts and Wheel spacers. Wheel spacers are essential components that are used to create additional space between the wheel hub assembly and the wheel. They are designed to improve vehicle stability, enhance handling, and allow for the installation of larger tires.

Wheel Accessories,Wheel Lug Nuts,Truck Wheel Spacers,Chrome Wheel Nuts,Aluminum Alloy,Wheel Spacers

Ningbo Yokelink Machinery Co.,Limited , https://www.yokelink.com